| Orig. Posting Date | User Name | Edit Date |

| Jan 1, 2016 04:04PM | gurunutkins | |

| Dec 31, 2015 02:08PM | triggerboy | |

| Dec 30, 2015 04:02PM | ADA005 | Edited: Dec 30, 2015 04:57PM |

| Dec 30, 2015 03:58PM | ADA005 | Edited: Dec 30, 2015 04:49PM |

| Dec 11, 2015 05:56AM | CooperTune | |

| Dec 10, 2015 08:58PM | Cheleker | |

| Dec 10, 2015 06:54PM | velopackrat | |

| Dec 10, 2015 05:21PM | 66Cooper'S | |

| Dec 10, 2015 01:52PM | swindrum | |

| Dec 10, 2015 12:40PM | Tagus | |

| Dec 10, 2015 12:30PM | Cheleker | |

| Dec 10, 2015 09:08AM | Alex | |

| Dec 10, 2015 09:00AM | minimans | |

| Dec 10, 2015 07:19AM | ADA005 | |

| Dec 9, 2015 09:25PM | DRMINI | |

| Dec 9, 2015 03:33PM | Cup Cake | |

| Dec 9, 2015 02:22PM | turbodave | |

| Dec 9, 2015 12:50PM | ADA005 | |

| Dec 9, 2015 12:45PM | Tagus | |

| Dec 9, 2015 12:24PM | ADA005 | Edited: Dec 30, 2015 04:55PM |

|

Total posts: 397

Last post: Sep 27, 2018 Member since:Jul 29, 2008

|

Cars in Garage: 1

Photos: 107 WorkBench Posts: 1 |

|

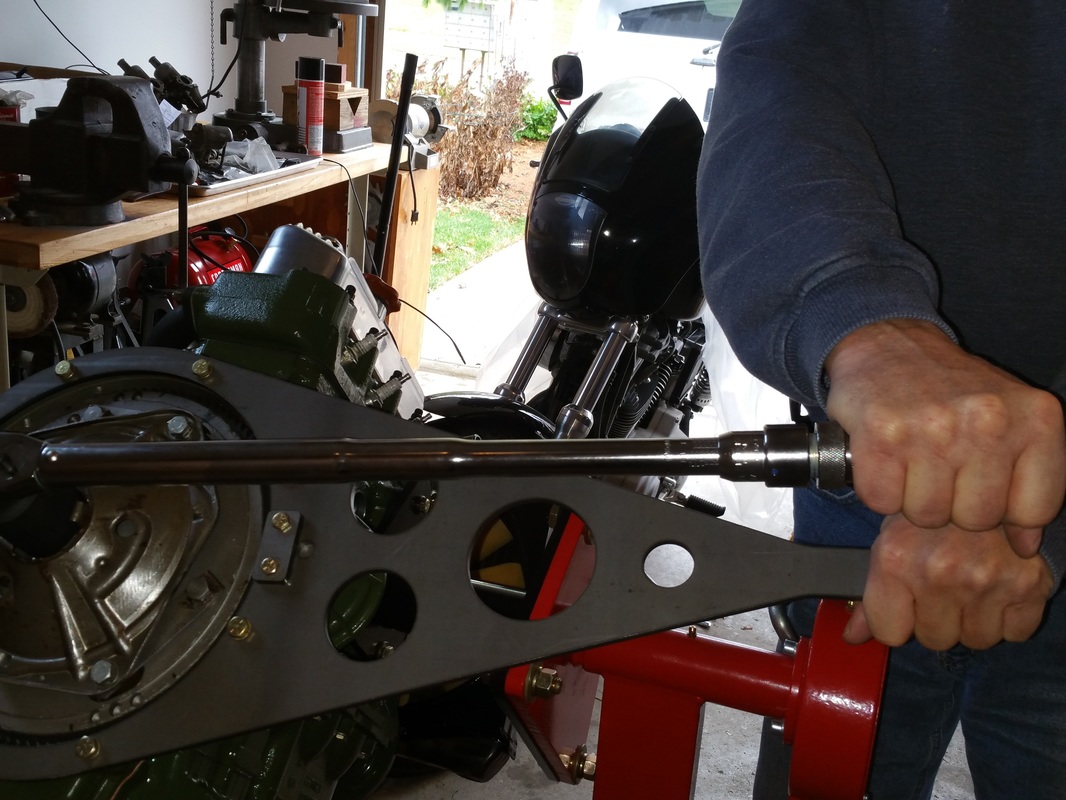

It's been a few weeks since I have checked in here. Yesterday, I picked up a batch of the flywheel immobilizer kits (as shown here) from the laser cutting shop. I have offered them to my Ohio Mini owner friends at $33 per kit, plus Ohio sales tax if I sell them at a meeting, which is a fair price. If you are interested, leave a note on this thread. Note that the "claw" engages more than one tooth, unlike a cut up flywheel ring gear. Also, this "claw" is for a 107 tooth ring gear. I don't have access to a later higher tooth count (120??) gear. If someone in SE Michigan has a 120 teeth ring gear, I could measure it and pop out a suitable "claw" in short order.

Hi Keith

do you know the weight or could you guess at shipping price to the Seattle area?

thanks

Barri

some new cars, 99 disco II, 88 jag xj40, 76 cadilac de ville 500c.i. (8.2l), 74 450sl, 69 lotus 7, 61 countryman (restoration)

the best view is always from the point of no return

|

Total posts: 431

Last post: Mar 28, 2016 Member since:Oct 2, 2015

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

Wow!

Looks nice. Mine looks like this, but not as pretty. Two pieces of 1-1/4" angle iron welded together, and two holes.

//www.ebay.co.uk/itm/201480050758?rmvSB=true

thanks turbodave for giving away your design and measurements for free.

|

Total posts: 29

Last post: Jul 22, 2016 Member since:Jun 22, 2014

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

These days, I prefer an immobilizer with a torque reaction arm...

I am too old to loosen the flywheel fastener, reef on the taper joint breaker, or torque the fastener to spec, while wrangling with the power unit on the bench or floor, or bashing around the engine compartment. The torque reaction halo+arm makes the job a breeze. I realize that it might be "over the top," but it helps this old Mini afficianado.

Merry New Year fellow Mini lovers!

Keith

|

Total posts: 29

Last post: Jul 22, 2016 Member since:Jun 22, 2014

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

It's been a few weeks since I have checked in here. Yesterday, I picked up a batch of the flywheel immobilizer kits (as shown here) from the laser cutting shop. I have offered them to my Ohio Mini owner friends at $33 per kit, plus Ohio sales tax if I sell them at a meeting, which is a fair price. If you are interested, leave a note on this thread. Note that the "claw" engages more than one tooth, unlike a cut up flywheel ring gear. Also, this "claw" is for a 107 tooth ring gear. I don't have access to a later higher tooth count (120??) gear. If someone in SE Michigan has a 120 teeth ring gear, I could measure it and pop out a suitable "claw" in short order. Drawing software with parametric constraints is a thing of beauty.

//www.wkeithadamspe.com/uploads/4/7/2/6/4726944/3498924_orig.jpg

//www.wkeithadamspe.com/uploads/4/7/2/6/4726944/6503472_orig.jpg

//www.wkeithadamspe.com/uploads/4/7/2/6/4726944/3143519_orig.jpg

Sorry, I couldn't use the image tool without messing up the aspect ratio...

|

Total posts: 4134

Last post: Oct 13, 2020 Member since:Oct 8, 2011

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I also did my first mini tranny in 1968 and was shown the flat blade screw driver trick. I have since taken to using a main bearing shell. The pictures have given me an idea for a tool I would like to have. Better drag out my drawing board. Steve (CTR)

|

Total posts: 10330

Last post: Jan 27, 2021 Member since:Dec 3, 2002

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

swindrum. Yes, made by Aaron Anderson.

|

Total posts: 247

Last post: Sep 1, 2019 Member since:Jun 26, 2012

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I too made a tool to accomplish the same task. It was a neccessity and time was short. And it's too ugly to share on this forum.

But ADA's tool is absolutely top shelf.

Who reading this thread wouldn't pay $20-$50 on the spot when the situation is staring you in the face? Nice tools are a beautiful thing.

|

Total posts: 3523

Last post: Jul 9, 2023 Member since:Feb 26, 1999

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

|

Total posts: 1456

Last post: Jan 31, 2022 Member since:Sep 8, 2003

|

Cars in Garage: 1

Photos: 186 WorkBench Posts: 0 |

|

Like minimans I used a screw driver for decades...until someone made me something similar to, but not as "sophisticated" as Kens. SO much nicer.

Chuck, did you get one of Aaron's that he made a few years ago? They are awesome.

Same basic idea, just a bit more rustic

Sean Windrum

1996 MGF VVC

1970 1275 GT Racer

66 Austin Countryman

63 997 Cooper (Under Construction)

63 MG 1100

|

Total posts: 438

Last post: Nov 13, 2022 Member since:Mar 27, 2002

|

Cars in Garage: 0

Photos: 15 WorkBench Posts: 0 |

|

Ever since I did my first clutch job on a Mini in 1968, I have used most of the various field improvisations to immobilize the flywheel. I always wanted something purpose built, and thanks to design tools with parametric constraints and a nearby and cooperative laser cutting firm, I can do so quickly and relatively inexpensively. The process is entertaining and fun.

Parametric? SolidWorks? SW is what I use. Drawing up some Moke panels right now.

Ron

|

Total posts: 10330

Last post: Jan 27, 2021 Member since:Dec 3, 2002

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

Like minimans I used a screw driver for decades...until someone made me something similar to, but not as "sophisticated" as Kens. SO much nicer.

|

Total posts: 10255

Last post: Jun 25, 2024 Member since:Mar 24, 1999

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I use both halves of a bearing shell - one half bent to the right shape for inertia ringgear, and the other half for pre-engaged.

Nice looking tool though.

|

Total posts: 1404

Last post: Jun 21, 2018 Member since:Oct 8, 2013

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

45 Years and all I've ever used is a large flat bladed screw driver..............

Mini's are like buses they come along in a bunch

|

Total posts: 29

Last post: Jul 22, 2016 Member since:Jun 22, 2014

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

Ever since I did my first clutch job on a Mini in 1968, I have used most of the various field improvisations to immobilize the flywheel. I always wanted something purpose built, and thanks to design tools with parametric constraints and a nearby and cooperative laser cutting firm, I can do so quickly and relatively inexpensively. The process is entertaining and fun.

|

Total posts: 8645

Last post: Dec 16, 2020 Member since:Oct 27, 2000

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

I sit an old 2" main bearing shell in there, it works just fine.

Kevin G

1360 power- Morris 1300 auto block, S crank & rods, Russell Engineering RE282 sprint cam, over 125HP at crank, 86.6HP at the wheels @7000+.

|

Total posts: 10335

Last post: Aug 19, 2016 Member since:May 13, 2001

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

A short piece of angle iron by itself works for me.

The power of accurate observation is commonly called cynicism by those who have not got it. G.B.S. Sarcasm is the lowest form of wit. Oscar Wilde

//www.cupcakecooper.ca/

|

Total posts: 3660

Last post: Feb 18, 2017 Member since:Jul 10, 2001

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

|

Wow!

Looks nice. Mine looks like this, but not as pretty. Two pieces of 1-1/4" angle iron welded together, and two holes.

//www.ebay.co.uk/itm/201480050758?rmvSB=true

It's been fun, but this place is done. I have no hatred, and appreciate the good times. But this place now belongs to Tony and his pink mini.

|

Total posts: 29

Last post: Jul 22, 2016 Member since:Jun 22, 2014

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

I have a request for quote in to laser cut ten more. I'll let you know how much when I hear back from the shop. I am not inclined to let my drawings go for free....

|

Total posts: 438

Last post: Nov 13, 2022 Member since:Mar 27, 2002

|

Cars in Garage: 0

Photos: 15 WorkBench Posts: 0 |

|

Would you happen to have DWG or DXF files for those parts? I would love to have a set cut. Great idea...

Ron

|

Total posts: 29

Last post: Jul 22, 2016 Member since:Jun 22, 2014

|

Cars in Garage: 0

Photos: 0 WorkBench Posts: 0 |

Here is a flywheel locking tool that I use...

FB failed, so here are some photos from my stagnant web page...

//www.wkeithadamspe.com/uploads/4/7/2/6/4726944/3498924_orig.jpg

//www.wkeithadamspe.com/uploads/4/7/2/6/4726944/6503472_orig.jpg

//www.wkeithadamspe.com/uploads/4/7/2/6/4726944/3143519_orig.jpg